TECHNOLOGY

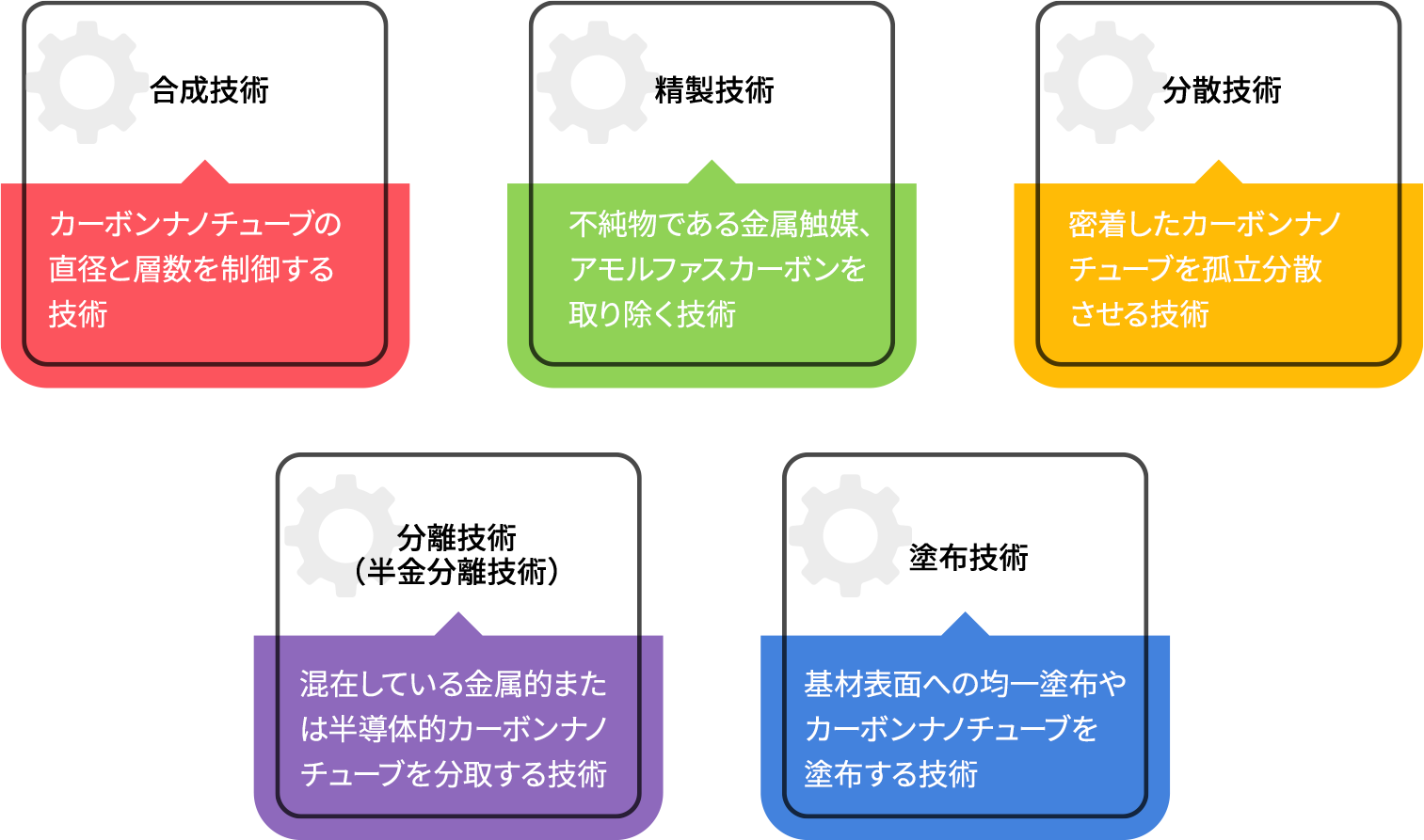

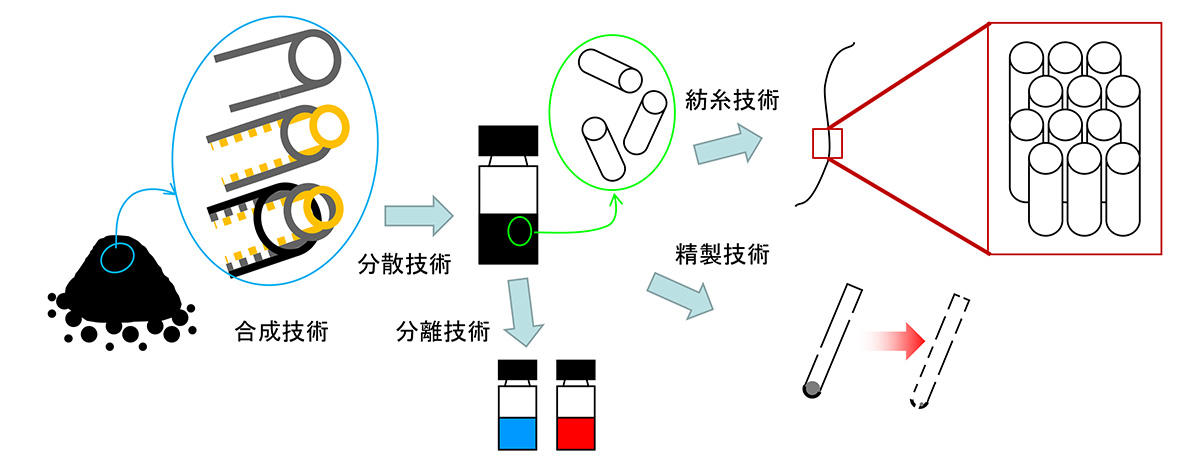

CNT technologies

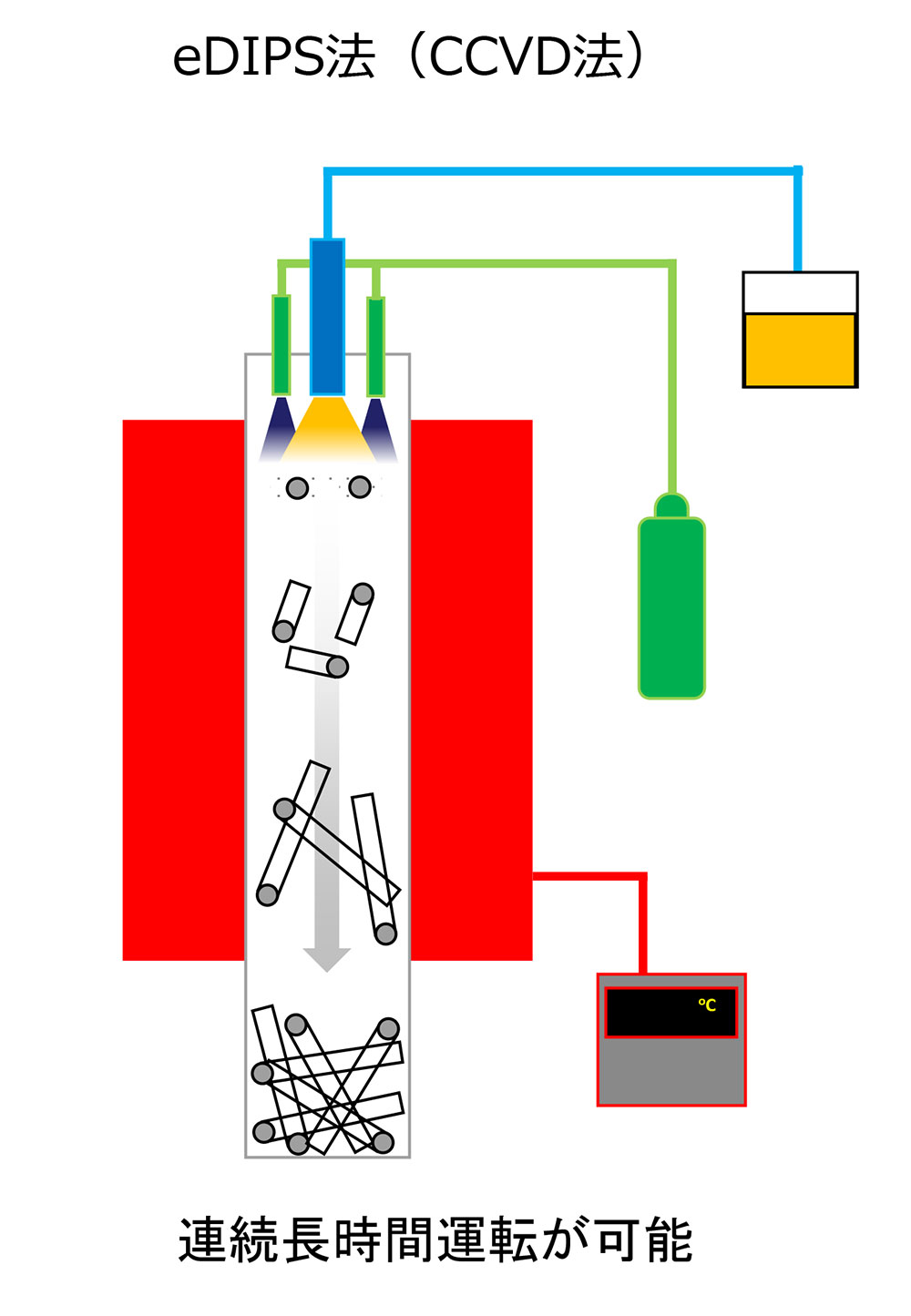

Synthetic technology - MEIJO eDIPS -

The MEIJO eDIPS method is a type of vapor-phase flow method based on chemical vapor deposition (CVD).

In this method, metal catalyst and carbon source are sprayed in a mist form from a nozzle at the top of the reaction tube, using a carrier gas (H2) for supply. The metal nanoparticles are suspended and during the flow process from the upper to the lower part of the reaction tube, single-walled carbon nanotubes are synthesized in a cotton-like structure and deposited in the collection chamber at the bottom of the reaction tube.

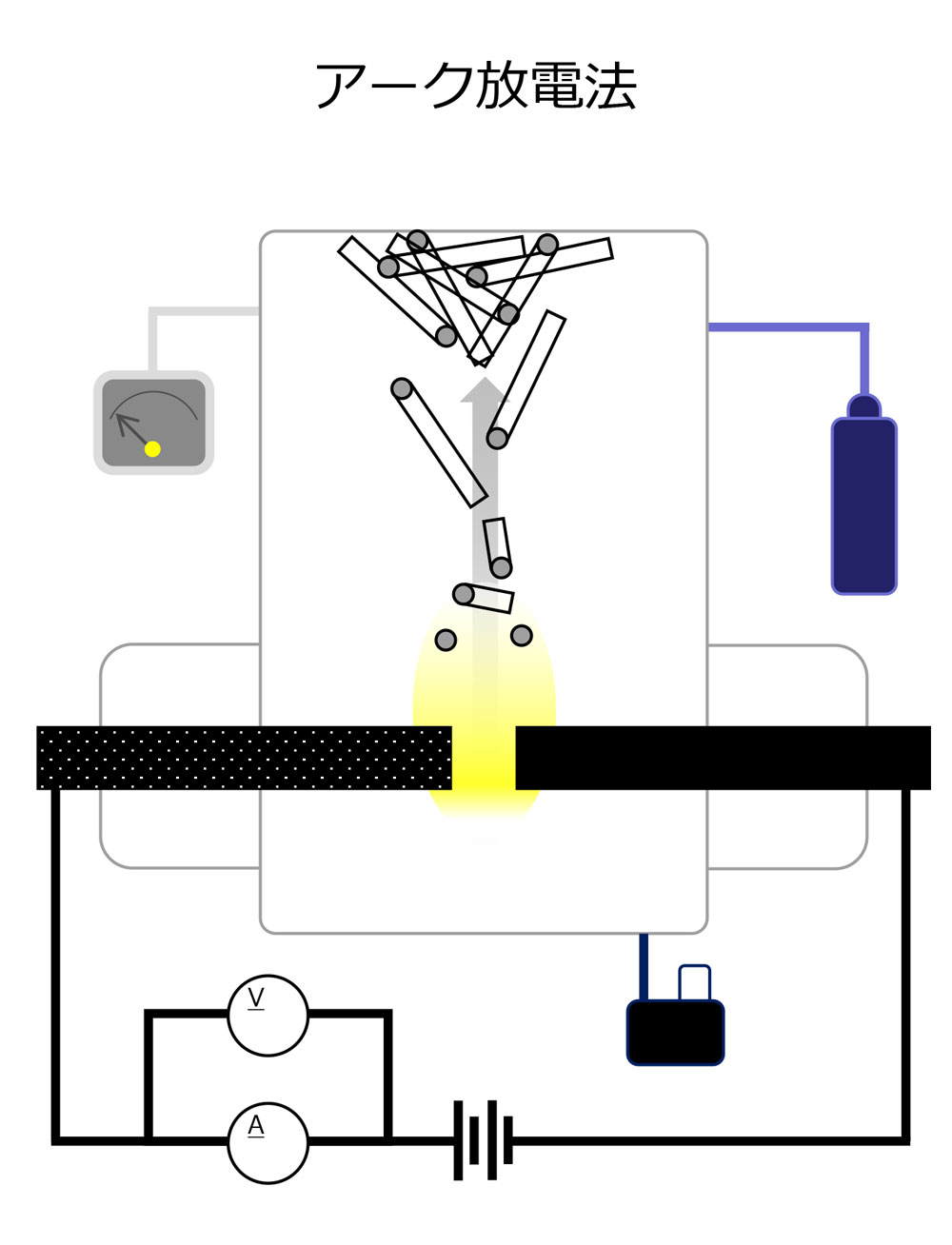

Synthetic technology - MEIJO Arc -

The arc discharge method is a synthesis technique where an arc discharge is generated between two carbon electrodes, causing the anode electrode to vaporize due to the heat, resulting in the formation of single-walled carbon nanotubes (SWCNTs).

The carbon electrode on the anode side is doped with a metal catalyst. When the electrode vaporizes, the metal catalyst also evaporates into a gaseous state, serving as a starting point for the generation of single-walled carbon nanotubes.

The carbon electrode on the anode side is doped with a metal catalyst. When the electrode vaporizes, the metal catalyst also evaporates into a gaseous state, serving as a starting point for the generation of single-walled carbon nanotubes.

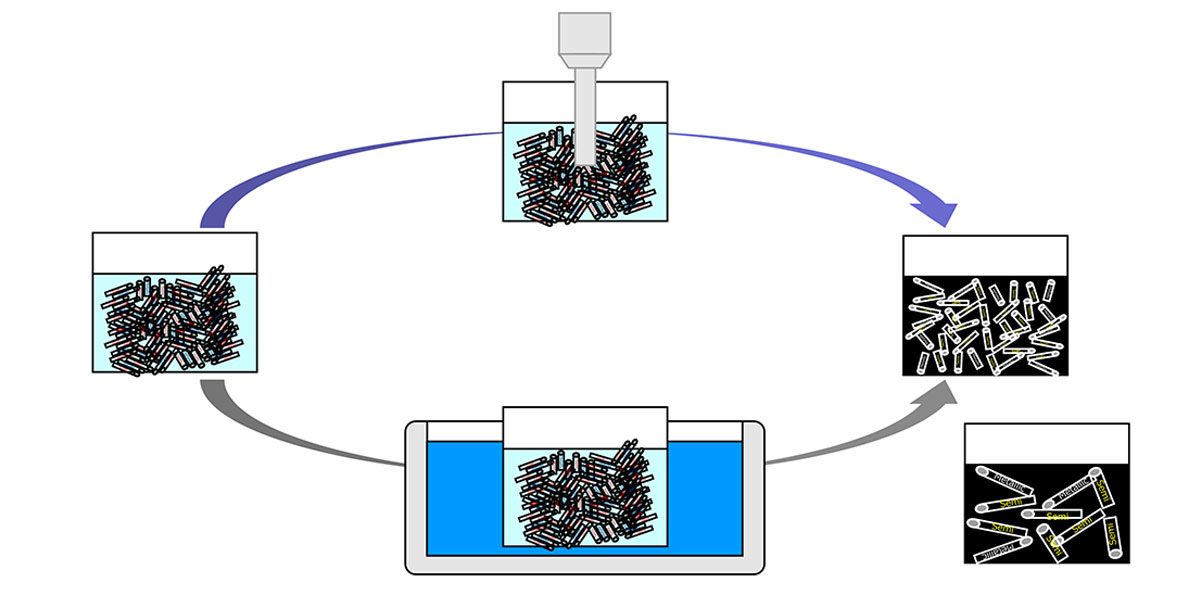

Purification technology

During the synthesis of carbon nanotubes, it is common to use a metal catalyst as a starting point for their growth. However, immediately after synthesis, the nanotubes may contain impurities derived from the catalyst, as well as carbon impurities. Therefore, a purification process is necessary to remove these impurities after synthesis. Our company possesses reliable purification techniques to achieve high purity levels in carbon nanotubes.

Dispersion technology

Carbon nanotubes (CNTs) tend to form bundles or agglomerates due to strong π-π interactions and van der Waals forces, making their dispersion difficult in water and organic solvents. Furthermore, it is crucial to achieve dispersion without compromising the aspect ratio (length) of CNTs in order to exhibit their electrical and thermal conductivity properties. At Meijo Nanocarbon, we have developed a proprietary technique called the MN method, which enables high conductivity dispersion while maintaining a high aspect ratio of CNTs. This breakthrough allows for the realization of their desirable electrical and thermal properties.

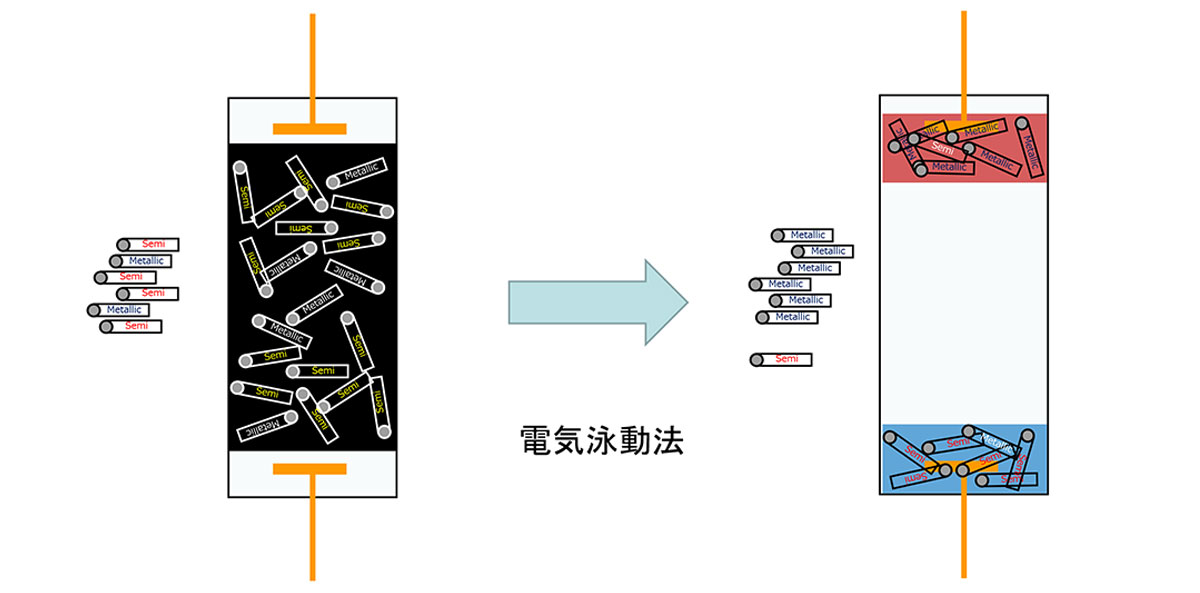

Separation technology

NEC and the National Institute of Advanced Industrial Science and Technology (AIST) have successfully developed a technique called the Electric Field-Induced Layer Formation (ELF) method for the separation of high-purity semiconductor-type single-walled carbon nanotubes (SWCNTs) without the use of ionic surfactants. With this method, they achieved a separation purity of over 99%. This breakthrough enables the production of high-performance ink materials without the need for dispersants that can negatively affect device performance.

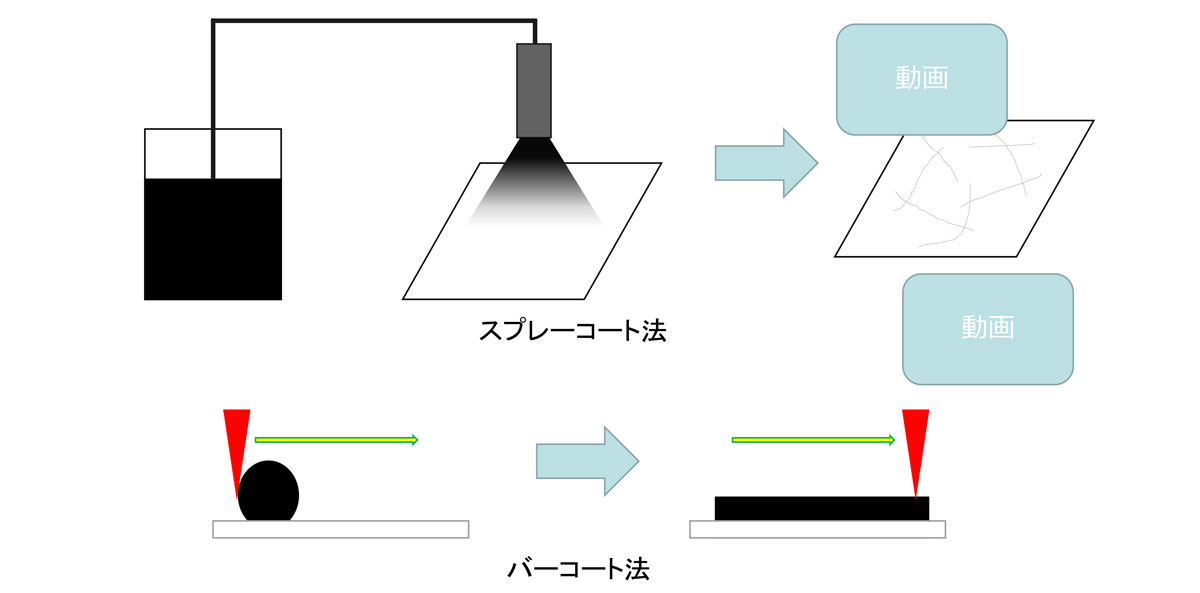

Coating technology

We have two types of coating methods, spray coating and bar coating, for the dispersion liquid used in our company. The spray coating is customized for CNT specifications and optimized to instantly dry easily agglomerating CNTs during substrate spraying, ensuring the dispersion state is maintained while effectively depositing CNTs onto the substrate. This allows for the formation of a high-quality coating layer. On the other hand, the bar coating method is used to apply a uniform liquid film onto the substrate and is utilized based on specific applications or substrate requirements.